Locking Washer / Locking Plate and Its Use on Ships

Locking Washer / Locking Plate and Its Use on Ships

A locking washer or locking plate is a mechanical device used to prevent nuts and bolts from loosening due to vibration, shock, or dynamic loads. On ships, where machinery and structures are constantly exposed to heavy vibrations, rolling, pitching, and fluctuating stresses, securing fasteners is extremely important for safety and reliability.

Function

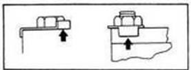

The locking washer/plate is fitted under the nut or bolt head.

After tightening, the washer tab or plate edge is bent against the flat of the nut or bolt to hold it securely.

This prevents the nut or bolt from rotating and coming loose under vibration.

Uses on Ships

Engines & Machinery – Locking plates are used in main engines, auxiliary engines, pumps, and compressors to secure critical fasteners.

Hull & Deck Fittings – They are used in structural joints, hatch covers, and deck machinery where loosening could compromise watertight integrity or safety.

Steering Gear & Propulsion Systems – Essential in securing parts where failure due to a loose nut could lead to loss of maneuverability.

Advantages

Simple and reliable design.

Provides positive locking without relying solely on friction.

Easy to inspect visually for security.

Conclusion

On board ships, where operational safety depends on the reliability of every component, locking washers and locking plates are vital for securing fasteners against loosening. Their proper use ensures machinery safety, structural integrity, and the overall seaworthiness of the vessel.

Shaft Key and Its Use on Ships

A shaft key is a small but essential component used to connect a rotating machine element (such as a gear, pulley, or coupling) to a shaft. It transmits torque and prevents relative motion between the shaft and the mounted part.

Function

The key fits into a slot (keyway) cut on both the shaft and the mating hub.

This mechanical connection allows torque transfer without slipping.

It also helps in aligning rotating parts accurately.

Uses on Ships

Main Engine and Propeller Shaft – Keys are used to fix couplings and gears to the shaft, ensuring reliable power transmission.

Auxiliary Machinery – Pumps, compressors, and alternators use shaft keys for secure rotor and pulley connections.

Deck Machinery – Winches, windlasses, and steering gear employ keys for torque transfer in their drive systems.

Advantages

Simple design with high strength.

Easy to install and replace.

Provides positive drive between shaft and component.

Lock Nut and Its Use on Ships

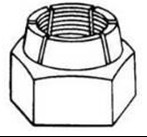

A lock nut is a type of nut specially designed to resist loosening under vibration, torque, or dynamic loads. Unlike ordinary nuts, lock nuts use friction, mechanical deformation, or additional locking elements to secure fasteners in place.

Function

Prevents nuts and bolts from loosening during continuous vibration.

Can be used with or without washers depending on application.

Ensures a strong and reliable fastening.

Uses on Ships

Engines & Machinery – Secures bolts in main and auxiliary engines subject to constant vibration.

Propeller & Shaft Couplings – Used to hold coupling bolts and critical rotating components.

Deck Fittings – Applied in winches, windlasses, and cranes where fasteners must remain tight.

Advantages

Stronger locking compared to normal nuts.

Available in different types (nyloc, jam nut, castellated, etc.).

Reliable even under repeated stress.

Conclusion

On board ships, lock nuts are essential to prevent loosening of fasteners in vibrating and high-stress environments, ensuring machinery safety, operational reliability, and preventing accidents.